What Does Surface Treatment Do?

You’re probably here because you have a problem – you need to write or print or stick something to a certain surface as part of your wider production process, but it’s not working. Have you ever wondered why?

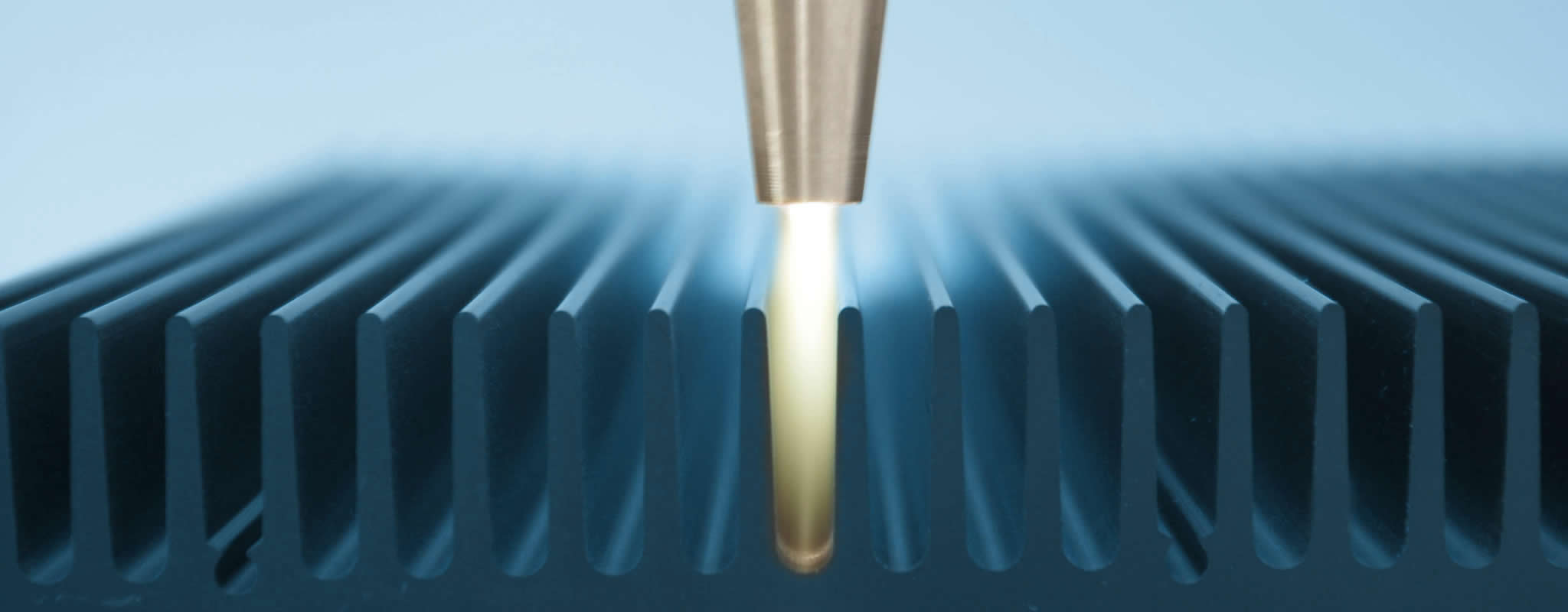

In simple terms, the reason for this is the relative energy between two surfaces – and the only way to solve the problem is to modify a surface to increase its adhesive capability. This is what’s known as “Surface Treatment”. The two solutions we work with are Corona surface treatment (also called Corona discharge treatment) and Plasma surface treatment (also known as Atmospheric Plasma treatment). Surface treatment is often at the heart of a production process and can play a vital role in successfully reaching the outcomes you desire in your finished product.

Corona discharge treatment is usually – although not always – the lower cost option when it comes to surface treatment. In fact, in probably 95% of cases, Corona surface treatment of a substrate is still the perfect way to improve surface adhesion and deliver a first-class product. However in the remaining 5% of cases, Corona surface treatment will not work because of the complexity of the chemical make-up of the substrate. In these situations, Plasma surface treatment is needed to allow a secure bond. Plasma surface treatment can be used in rather more subtle ways and sometimes can give better results.

The simple difference is that where the Corona surface treatment process is carried out in ambient air, Plasma surface treatment requires a controlled environment and the use of a dopant gas. We’ll explain the processes in a basic detail on our Plasma Surface Treatment and Corona Surface Treatment pages. If you’d like to have a more in-depth understanding of each technology, then Bradley will be more than happy to speak with you and explain in as much detail as you’d like to know.

Working with our key supply partners – AFS, Softal, AcXys and Consultex Systems – we have combined knowledge of a vast range of process requirements, gained from experience of working with customers in a wide range of Industry sectors. Whatever the needs of your Application, Active Surface Technology can probably provide the solution – from the treatment of intricate 3D or pocketed components or tiny areas of them, through to films in excess of 10 metres wide. On the rare occasion that we can’t assist, we’ll undoubtedly be able to guide you in the right direction.

Our Supply Partners: AFS, Softal, AcXys Technologies & Consultex Systems

We work closely with our Supply partners AFS, Softal, AcXys Technologies and Consultex Systems, supplying their equipment around the UK and Ireland to customers from various industry sectors with lots of different requirements.

The technologies offered by each Supply partner complement one another well, which is what sets Active Surface Technology apart from the other Surface Treatment suppliers in the UK – we have the breadth of product to be able to offer our Customers the right solution to achieve their desired outcome precisely – not just something that “will do”.

Production process demands are constantly changing and evolving; we are always happy to speak with other Surface Treatment providers whose methods might add value and differentiation to our product portfolio. For more information, please speak with us on +44 (0)1844 355221 or email enquiries@activesurfacetech.co.uk